2011-DEC -> Cabin Complex Renovation Project Status for 2011

|

Our Cabin Complex Renovation Project has necessarily extended into 2011. Construction began in April 2009 (see 2009 Monthly Archive). Work continued throughout 2010 (see 2010 Monthly Archive), but we have had to again recalibrate our completion date to Fall 2011. This construction effort has indeed transformed our property into a fully-functioning, year-round, business event and agri-tourism destination, but the scope and difficulty grew over time as well. We are diligently working to complete the interior of the Cabin and the final touches on our outdoor Wood-fired Oven. Please continue to check back each month to see our progress in 2011, and for the announcement of our Grand Opening celebration this Fall. [Progress Photos below taken January 31, 2011] Our efforts this month have completed a myriad of diverse tasks – each necessary to complete our project:

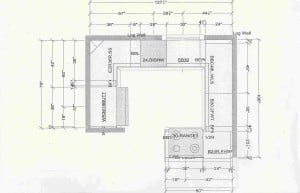

In the photo to the right, see a new 16′ gate, as well as a completely revamped corner fence and repositioned water barrel. These changes widen the entranceway for overflow parking from the Cabin complex. Stone (crush-and-run) will be added to provide mud-free vehicle access to our front pasture. Speaking of pasture, we had to purchase (and unload) a tractor-trailer load (42 – 4’x5′ round bales) of hay to extend our hay supply through what has become an unusually long and cold winter. Our annual property conservation easement inspection was performed on January 28th by the Tar River Land Conservancy. I walked the entire property perimeter with Amy Edge – re-enacting an historic North Carolina requirement to once a year, re-visit each property corner to demonstrate your knowledge of the land, and thereby retain ownership. Additional framing was completed on the loft walk-in shower to create a shower seat and accommodate the routing of the exhaust pipe from our Island Range Hood in the Kitchen below (see photo to the right). Final plumbing of the stacked Washer/Dryer and emergency drain was also completed. The Kitchen design has been finalized (see plan-view below) and includes: an oversized Refrigerator/Freezer, Dishwasher, Sink, Electric Range, stainless-steel Island Range Hood and antique-iron Pot-Rack. Cabinetry is below counter; the counter-tops will be granite; with open wooden shelving installed above – thereby maintaining a rustic look with exposed logs and chinking. This small, but efficient, Kitchen opens to the Cabin living room and back porch and is designed to support cooking demonstrations. We are still awaiting delivery of a few back-ordered electrical and plumbing fixtures. Final plumbing and electrical rough-in will be finished in February. The Island Range Hood will be installed and the Kitchen ceiling-soffit framing completed. Final furring of the basement block walls will be performed. Once we insulate the Cabin, tile-work in the both the loft and basement bathrooms, log-chinking and sheet-rocking can proceed. Keep in mind that we estimate Cabin insulation is a 2-day job; sheet-rocking a 3-day job; log chinking a 4-day job; bathrooms, an 8-day job These are high impact tasks. Kitchen cabinets, trim work and painting, and oak board floor installation follow. The end is in sight. [Progress Photos below taken February 28, 2011]

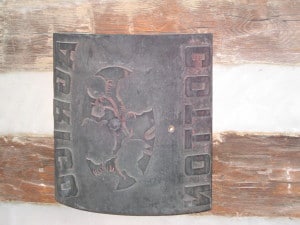

A new chase wall was built to accommodate the 6″ Kitchen stove exhaust pipe (below, on main floor). Re-routing of this pipe was necessary to avoid cutting through a “collar” log above the Kitchen window. Kitchen plumbing (concealed in a soffit) altered our original plan to vent through the Cabin side-wall. We now are venting through the back-wall above the roof-line of the Cabin back porch. On the Cabin main floor work began on the Kitchen soffit and island range hood installation. This work will be completed in March, after the last of the Kitchen electrical wiring is installed to support the Electric Range, Range Hood, Dishwasher and Garbage Disposal Unit.

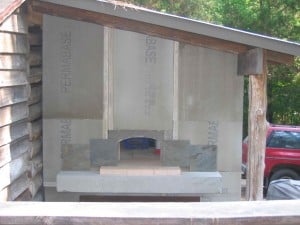

There were a few days in February when we could have performed masonry work on our outdoor, Wood-fired Oven, but we opted to wait until March for longer stretches of warm weather. Additional fire-bricks will be purchased to complete the Oven construction. Only a cast-in-place Oven exhaust transition (rectangular to circular shape) and a sufficient length of double-walled pipe to vent above the existing Shed roof peak are needed to create a functioning Oven. Other decorative siding and tile-work will be added once the Oven is “cured” and fire-tested. By the way we had our first new calf this month – others are on the way – it’s Spring you know. The photo shows a day-old heifer calf – incredible! Check back next month. We are staying on schedule. Much of the construction work thus far has been sequential in nature. We are transitioning to the final phases which helpfully become parallel in nature, thus compressing our timeline to completion. Progress Photos below taken March 31, 2011

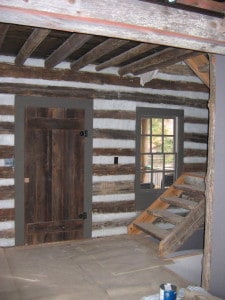

The Oak trees were felled over four years ago by Mike Wheeler (Logs-to-Lumber) and cut into 5/4 lumber with a portable Band Saw in Wilton, NC; the rough cut boards have been drying in our Shed Barn since then. Needless to say, when you walk into the Cabin, the floor has quite a story to tell – like much of the Cabin – not your ordinary structure. The living-room photo above shows the boxed-in steel, ceiling beam that will soon be “covered” with weathered barn board to give the appearance of a large rough-cut wooden beam that spans over 14 feet.

The electrical and plumbing rough-in for the entire Cabin is finally complete. Only the Loft HVAC unit remains to be installed (after sheetrock). Other activities completed during March included (among others): 1) We sold our first and only “get-out” calf this week. For those unfamiliar with cattle – occasionally you have one that is determined to venture outside the fenced pasture. Despite all my containment strategies, I finally came to the conclusion that the only solution – for my sanity and the safety of the animal – was to sell her at auction. This was the first and only cow since I have kept cattle at Lynch Creek that behaved in this manner. I hope its a long time before I have another like her. 2) In preparation of acquiring a new flock of chickens, we totally cleaned and repaired our chicken coop and containment fencing. Age and predators had taken their toll on my Plymouth Barred Rock flock. I am thinking of changing breeds, but have not yet decided – stay tuned. 3) In a defensive erosion control measure we seeded pasture grass along the driveway fence line of our front pasture. Downed trees and new landscape plantings disrupted the existing cover in a sloped area subject to runoff. Usually we would seed in the fall, but storm damage over the winter created a problem area. Hopefully we can establish a cover before the heat of summer. In another erosion control measure, we expanded the new entranceway berm near the Cabin and installed drain pipe from the driveway drain edge under the berm to the woods. 4) Twice a year we “winterize” our outside water lines and creek pump. We re-installed and electrified our pump in Lynch Creek and tested all drained water lines that supply hose bib outlets on the property. Hopefully our below freezing temperatures will not return until Fall. 5) It was time to once again pump our property septic tank(s). Generally every five years or so is recommended. With a country property, you pay no water and sewer bill, but in turn have total responsibility for the maintenance of your well and septic tanks; we have no garbage collection services, and haul our waste to the County convenience centers or landfill; we have no street cleaning services and pickup litter along our quarter mile road frontage weekly; we rely, only as needed, upon calling County Sheriff and Volunteer Fire for emergency services. 6) Joey Hite, our farrier, came to trim Molly’s (the donkey) feet. She had terrible hooves when I purchased her, and it’s taken about two years to finally get her sound. Quarterly trimming and Coppertox seem to have been the trick. She’s finally running and walking fine in both dry and wet weather. There were times when I just wasn’t confident we could ever get her fixed. She’s our guard animal for the cattle; loves the baby calves; and fends off all threatening intruders to the pasture. We’ve been extremely busy. The cold and rainy spell at months-end slowed our outdoor activities somewhat, but progress inside the Cabin remains on schedule. Check-in next month to begin seeing us finish-up the Cabin interior. Progress Photos below taken April 30, 2011 Both the Basement and Loft bathrooms have been prepped for tile work that will begin next week (see our upcoming May progress report for photos). Durock cement board has been applied where needed.

Next month we will: spray insulate and chink the log joints; finish paint the wall board and trim out the windows and baseboards; Oven brickwork should be completed; kitchen preparation should begin; bathrooms should be complete. While it does not look like we will be totally finished by the end of May, let’s see what remains to be completed at the end of May. Come back and see; pencil-in July 4th on your calendar for our opening party! (whew – this month ends two years of continuous work on our Cabin complex renovation project – gotta get it done) Progress Photos below taken May 31, 2011 Well, it’s May (and we’re not done yet), but a tremendous amount of work has been completed.

1) Spray “hard” foam insulation between the logs (white expanded foam on the left wall of the photo) 2) Cut and nail wire lath between the log joints (black paper backed wire on the right wall of the photo) 3) Apply special mortar mix to “seal” the inside log face and act as “chinking” (clay mud in the old days) 4) Cleaning up the entire Cabin (big job).

Considerable progress was made on the wood-fired Oven. The Flue transition (from rectangle to circle) was formed and cast with special high-temperature “Metalcast” concrete. The transition shape was formed with styro-foam and removed after the pour hardened. An 8″ stainless steel Duravent base plate was fitted to the top of the transition and attached with anchor bolts embedded in the concrete.

The outdoor Patio areas are complete and were used this month for the Annual Picnic of the Louisburg O’Henry Book Club.

The living room Oak Floor installation continues and will be completed shortly. On the farm side, our potato garden is progressing well; we harvested Spring hay for use next winter; we “lent” a bull to our neighbor’s cow herd; gave the swarm of bees to a “first-time” beekeeper; had an additional calf born; planted basil seed; and continue working hard in the Summer heat. Progress photos below taken June 30, 2011 Although in a severe drought, we planted vines to obscure our HVAC equipment in the sideyard.

All final sheetrock touchup and prime painting has been completed (basement and loft bathrooms). At month-end we are busy preparing for our Ben Franklin Society 4th of July Open House – promotion, cleanup, food prep, etc. It’s been really hot and dry this month! Baby calves keep coming, but we are already feeding hay (the grass is dormant/dry) which is a bad harbinger for next winter – but the cows must be fed. We need rainfall badly. Final electrical and plumbing installation work will be completed in July. Inside trim work will begin for all windows and doorways. The kitchen cabinet installation will be the last major work expected to be later this summer. The end is in sight, but the devil is in the details. On the farm side, we had to replace our walk-in cooler compressor that was destroyed a few months ago by a lightning strike. Our potatoes are still in the ground and awaiting the cooler for long-term storage. Some farm philosophy: Never a day goes by without a surprise (good and bad) on a farm. If you have a game plan, it will always change due to a crisis. Everyday can always find a way to get longer – on shorter days you just work in the dark. Cannot wait to see what tomorrow brings. Progress Photos below taken July 31, 2011 Well, July has been (I think) the hottest month on record in North Carolina history. So many days over 100-deg-F with high humidity that I’ve lost count. I was consumed with the conflicting demands of calving, digging potatoes and oven brickwork this month, while trying not to die from heat exhaustion. If you work all day in air conditioning, it’s hard to imagine how working 7-days-a-week outside wears you down. In spite of these obstacles, we continued to make progress on the Cabin.

All electrical work has been completed in the Cabin (by Stancil Moss) – all outlets, ceiling and track lights, wall sconces and ceiling fans are installed and operational. Only the kitchen final equipment hook-ups remain to be completed. Final plumbing fixture-connection work in the two baths and utility room are scheduled for completion in August.

Both Shallots and Basil were transplanted to our Hoop House. I plan to pull the double-poly plastic cover back on in September and grow vegetables this coming winter.

With the drought we have been experiencing, Lynch Creek has been at record low levels – so much so we have not, for the first time in fifteen years, been able to pump irrigation water from the creek. Needless to say we need rainfall – a lot of it. We hosted a July 4th Ben Franklin Society Open House event and had over forty folks attend. Some great food, company and conversation. Plan to come to our next event – Labor Day Weekend! Our Cabin Complex renovation Project should finally be completed this Fall – long overdue, but not overdone. Progress Photos below taken August 31, 2011

The late month hurricane Irene consumed a week of effort getting ready, enduring the event and finally cleaning-up the farm. We have several trees downed, but fortunately no significant structural damage. Our winds were higher than expected, but we had less rainfall – only about 2 inches. We have continued to weed our Hoop House plant beds and transplant fall Tomatoes. Our Basil and Shallots are doing fine. We will pull our plastic covers back on in September and resume Winter vegetable production we lost last year when our building collapsed in the January snow/ice storm. Really looking forward to growing inside again! We completed repairs to our creek pump that was damaged by the low stream flows we experienced earlier in the Summer. Water levels have returned to normal and our back-up irrigation and animal water supply is available as needed again. We added an additional truckload of crush-and-run to our entrance driveway to prepare it for the Winter months ahead. We have bush-hogged our rental fields in preparation of haying this September. NCDOT finally removed the silt-fencing on our roadway Bridge – to complete that project. We made repairs to our heated greenhouse shelving in anticipation of seedling propagation the Fall for transplant to our Hoop House. We researched and purchased a tenon-making tool that will enable us to use harvested Cedar limbs to build our rustic Cabin stairway railings. All Cabin interior finish carpentry will be completed this Fall and commence as soon as our Wood-fired Oven is completed outdoors. With Cabin heat and lighting in place – there should be no significant delays once we move indoors to finish-up the Cabin interior. Unfortunately we have decided to postpone or Labor Day Weekend event, and will schedule another celebration later this Fall. Hurricane Irene stopped our progress – dead in its tracks. The end is clearly in sight! Progress Photos below taken September 30, 2011

The intricacy of doing this increased as the Oven orifice became smaller. From the attached photos, you can see the typical compound cuts required. For each succeeding row, the brick segments became smaller and more difficult to mortar in place. The final “keystone” became two segments – making it easier to cut and shape the final brick segment. By using our home-made, radius-gauge tool we were able to maintain a perfect spherical shape with an inside diameter of 56 inches – making the dome height above the cooking floor 28 inches.

The companion photos below show the completed Oven dome covered with a 3 inch thick insulating concrete layer. This layer serves to keep the Oven heat inside. The temperature in the Oven can be up to 1000-deg-F. We expect the exterior surface temperature of the insulating concrete to only be about 100-deg-F.

We did preliminary tests of the Oven flue which performed perfectly. The scaffolding supporting our diamond-saw work platform for cutting the bricks has been dismantled. General site cleanup was completed. After the insulating concrete has cured for about a week, we will begin the Oven “curing” process, whereby we burn successively larger fires in the Oven over a period of another week – to dry-out all residual moisture from the Oven bricks themselves and the insulating layer. This process prevents cracking of the bricks and/or insulating concrete. Once the Oven is cured, it will be ready to use – by mid-October!! Other farm activities completed this month included: 1) The Kitchen soffit was painted and the Pot Rack and Vent Hood base support was reinstalled. 2) Two large trees downed by the hurricane were cut-up and the stumps removed. 3) Hay and re-seeding operations were initiated for our 25 acres of rented land. 4) Several additional calves were born and appropriately cared for. 5) The Cabin parking area was re-seeded to establish a permanent grassed surface. Late last fall we only stabilized the graded area to prevent winter erosion. 6) Garlic seed was procured to plant in the hoop-house this Fall. 7) All back pasture winter hay-feeding areas were re-seeded. 8) Fred Harris, from the NC Forest Service. inspected some IPS Beetle infestation in our pine grove adjacent to our main residence. We plan to remedy this problem and thin the 20 acre pine stand at the back of our property this winter. 9) We purchased a”Greyhound”, manual wood-splitter from Harbor Freight. We will need some good dry oak to burn in our Oven and Cabin fireplace(s) soon. 10) Additionally, electrical circuits were wired for an outlet to support our refrigeration (and other) equipment, as well as track lighting for the Oven facade work-area. We expect to christen our Wood-fired Oven by cooking Tomato Pie (a.k.a. Pizza) and celebrate the opening of the Franklin BreadWorks in October (announcement to follow). We should complete the interior of our Cabin by years-end – more to follow – check back here with us for details each month this Fall. Progress Photos below taken October 31, 2011

We “cured” the Oven starting on October 9th by burning a series of fires – small to large – over a two week period. This process slowly removed all moisture from the brick, masonry and concrete to prevent the rapid expansion (steam) of moisture which could potentially crack the Oven enclosure. During this process we measured internal brick and external insulating concrete surface temperatures with an infrared temperature “gun”. Once we verified that the external surfaces did not exceed 100-deg-F (as expected), we could safely enclose the Oven as shown in the photos. We are confident that our building is safe from fire hazard – either within the wooden enclosure or from flue temperatures at the rooftop level.

It only takes two hours to fire and heat the Oven to cooking temperature. Bob is shown cooking and cutting the first “Tomato Pie” baked in the Oven (on October 24th). Pies cook in three minutes or less. Crisp and delicious!

We are presently only using dry oak wood. After the first half-hour, there is no smoke from the chimney – the internal temperature approaches 800-deg-F. While the Oven is complete, we have some experimenting yet to do as we learn how to cook with this ancient technology. Wood-fired ovens have been used for centuries. There is something very special about cooking in this manner – a feeling of being connected with the past – very primal, permanent and reliable. Open fire cooking isn’t a new trend, but rather a sensible return to fundamentals – without the stress and fragility that accompanies modern technology.

Final painting has begun. Two finish coats will be applied to all sheet-rocked surfaces. The Cabin should be completed by years-end, with only some kitchen details lingering into next year. Other critical tasks completed this month include: 1) Our Hoop House was put back into production (link to our Press Release). We have added a permanent herb section this year for the first time – as well as a black fig bush. basil, garlic, shallots and tomatoes are growing already. Other winter vegetables will be planted soon. 2) We harvested our Fall Hay and re-seeded over twenty acres with oats, fescue and clover (link to our Press Release). 3) We purchased a new flock of chickens (Golden Comets) that will begin laying brown eggs soon. 4) We researched and procured bulk Bread Flour, Pizza Trays and a 20-quart Commercial Food Mixer in support of our start-up, Franklin BreadWorks project. Early next month, members of the Ben Franklin Society will experience the first “tastes” from our new Artisan, Micro-Bakery – more in next months update. Progress Photos below taken November 30, 2011

TV, Wi-Ex (wireless) coaxial cable and Antenna Rotor control connections have been installed from the Cabin exterior through the logs as shown in the photo to the right. OTA (Over-The-Air) HDTV reception is augmented by an Antenna Rotor for a 60-mile radius reception area. Our Wi-Ex cell phone signal amplifier assures strong cell phone reception (3,4 and 5 Bars) inside the Cabin for all service providers. This device also assures that we have Verizon 3G/4G wireless broadband internet connectivity. When coupled with our Dell Latitude Computer, InFocus LP70+ Display and large Projection Screen, all essential communication services are available to our onsite business clientele while they enjoy the serenity and seclusion of our convenient, but rustic facility.

The Cabin interior finish work will be complete by years-end, with only final Kitchen install work remaining into 2012.

I must admit that I am finally beginning to see the culmination of years of focused effort to create an integrated small farm operation – from farm-to-table. We look forward to begin sharing the fruits of our labor with you in 2012. Plan to hold a business meeting, or join us at a Franklin BreadWorks event, in 2012. We pledge to provide an outstanding facility and services that focus upon your comfort and success. Your support of our efforts will ensure that our Conservation Property becomes an integral part of the future of Franklin County’s evolving success story! Let us help you succeed, so that we can continue to thrive as well. Progress Photos below taken December 31, 2011

It’s been a while since I included an updated photo of the Cabin exterior. Everyone who visits tells us it looks like the Cabin has “always” been there. We take that as a sincere compliment – exactly what we have been trying to build. By the way, the chimney services two fireplaces – a traditional stone and firebrick hearth on the main-level, and a small, free-standing cast-iron one in the basement-level.

From the photo you can see that my new chickens have begun to lay beautiful brown eggs. I’ve missed having chickens for while and sure is nice to have fresh eggs daily.

On the Wood-fired Oven cooking utensil front, I finally was able to procure a 3/4″ wood tapping tool to adapt bristle brushes to standard wooden handles for “sweeping” and “cleaning” the Oven. Given the size of the Oven, custom tools are required to “work” the fire and food appropriately. On the winterizing front, I repaired/replaced an underground waterline shutoff that drains three faucets in the backyard shed area – completing my winterization for 2011. On the outside lighting front, we installed low-voltage lighting and adjusted the layout to provide essential evening light levels to satisfy our visual and safety concerns. Some construction updates: 1) Our interior pre-hung bathroom and glass shower doors were back-ordered and will be installed and trimmed in January; 2) The plumber has been on vacation and will complete some bathroom details in January; 3) All remaining 5/4 rough cut pine boards have been planed and readied for use as doorway trim in the Cabin. On the cooking front, I have adjusted my tomato pie (pizza) dough recipe, to accommodate the use of even higher protein flour that has added more “crunch” to the crust without sacrificing the balance of taste and texture. Everyone asks me for the recipe – after years of experimentation – I sadly have to forego publishing my recipe and technique. Do you really want to spend two days making dough? Come eat with us and enjoy the benefit of our work. Next you’ll want my sausage recipe, meatball recipe, pasta . . . . We wish everyone a healthy and prosperous new year. 2012 has to be better – doesn’t it? Plan to come visit us in 2012 – hold a business meeting at our Cabin – plan a social event on our Cabin Grounds – attend a private dining event and support our Ben Franklin Society fund-raising initiative – purchase some artisan breads and fresh produce – schedule a tour of our farm with your children. We are sure you will be pleasantly surprised. Stay tuned for more monthly updates in 2012. |

So far, it looks as if the landscape materials we planted around the Cabin Complex last year have weathered the drought and cold of winter. As well, we finally were able to spread the chicken-manure on our rented land (25 acres) in February. With some luck, we should have a bumper hay crop this year, and minimize our need to purchase hay to feed our growing cattle herd.

So far, it looks as if the landscape materials we planted around the Cabin Complex last year have weathered the drought and cold of winter. As well, we finally were able to spread the chicken-manure on our rented land (25 acres) in February. With some luck, we should have a bumper hay crop this year, and minimize our need to purchase hay to feed our growing cattle herd.

Leave a Reply